Ring PCB, your PCB & PCBA Turnkey Solutions | Professional Circuit

Manufacturing Expert

Ring PCB, your PCB & PCBA Turnkey Solutions | Professional Circuit

Manufacturing Expert

1.What are High-speed PCBs?

High - speed PCB refers to a printed circuit board designed for

high - speed signal transmission. Here are the details:

A high - speed PCB is a type of circuit board where the electrical

signals operate at high frequencies and data rates, typically above

1GHz or with rise and fall times less than 1 nanosecond.

2.Characteristics of High speed PCB:

- Low Signal Delay: The layout and materials are optimized to minimize the time it

takes for signals to travel along the traces, ensuring accurate and

timely signal transmission.

- Controlled Impedance: The PCB has precisely controlled impedance values of the signal

traces. This is crucial to prevent signal reflection and

distortion, which can occur when the impedance changes abruptly.

- Reduced Crosstalk: Special design techniques are employed to minimize the

interference between adjacent signal traces. This includes proper

spacing, shielding, and use of differential signaling.

3.Design Considerations

- Layer Stack - up Design: The arrangement of different layers,

such as signal layers, power planes, and ground planes, is

carefully planned to achieve the desired electrical

characteristics.

- Trace Routing: Signal traces are routed in a way that minimizes

their length and avoids sharp bends or discontinuities.

- Component Placement: Components are placed strategically to

reduce signal path lengths and to facilitate proper routing of

traces.

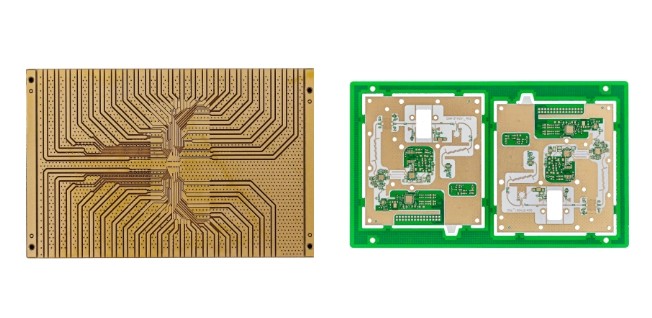

3. Customizable Design

Understanding diverse project needs, Ring PCB custom all kinds of PCB boards. Whether it’s adjusting layer structures, material selection, or

form factors, we ensure the boards perfectly match your product

requirements.

If you are interested in our Heavy copper PCB circuit boards,

please provide your customized needs, we will complete the sample

production within 7 working days, and complete mass production and

delivery within 15 working days.

4.Challenges of Manufacturing High-speed PCBs

1. Material Selection

High-speed PCBs require specialized materials with low dielectric

constants and low loss tangents to minimize signal degradation.

Ring PCB employs appropriate high-frequency laminates, such as

Rogers and Isola, ensuring optimal material selection based on the

specific application and performance requirements.

2. Impedance Control

Variations in impedance can lead to signal reflections and

crosstalk. Our engineering team utilizes advanced simulation tools

to design traces with precise widths and spacing, ensuring

consistent impedance. We also optimize the layer stack-up to

enhance signal integrity and minimize interference.

3. Signal Integrity and Crosstalk

High-speed signals are susceptible to crosstalk and noise, which

can degrade performance and reliability. Ring PCB employs

differential pair routing techniques and advanced layout strategies

to minimize crosstalk. We conduct thorough signal integrity

analysis and simulations to identify potential issues before

manufacturing.

4. Thermal Management

High-speed circuits generate more heat. We integrate effective

thermal management solutions, such as thermal vias and copper

pours, during the design phase. Our engineers analyze thermal

performance to ensure optimal heat dissipation throughout the PCB.

5. Precision Manufacturing

The intricate designs of high-speed PCBs require high precision in

fabrication, including fine trace widths and tightly packed

components. Ring PCB uses state-of-the-art manufacturing equipment

to achieve the precision. Our skilled operators and stringent

quality control measures ensure that each board meets exact

specifications.

6. Testing and Quality Assurance

We implement rigorous testing protocols, including AOI and ICT, to

allow early detection of issues, minimizing the risk of failures.

Here is a table of common parameters for high - speed PCB boards:

| Parameter | Description |

| Number of Layers | Up to 20 layers or(customizable) |

| Material Type | Such as FR - 4, Rogers RT/duroid series |

| Minimum Hole Size | Typically 0.2mm - 0.4mm |

| Line Width/Spacing | Usually 0.1mm - 0.3mm |

| Dielectric Constant | Varies by material, e.g., 3.0 - 4.5 |

| Dissipation Factor | Generally 0.01 - 0.05 |

| Copper Thickness | Common values are 1oz, 2oz |

| Board Thickness | Usually 1.0mm - 2.0mm |

| Surface Finish | HASL, ENIG, etc. |

5.Applications of High speed PCBs

High - speed PCBs are widely used in various high - tech fields,

including telecommunications, computer systems, aerospace, and

defense, where the reliable and efficient transmission of high -

speed signals is essential for the proper functioning of the

electronic devices.

At Ring PCB, we don’t just manufacture products—we deliver

innovation. With all kinds of PCB Boards, combined with our PCB,

PCB Assembly, and turn-key services, we empower your projects to thrive.

Whether you need prototyping or mass production, our expert team

ensures top-quality results.

17 Years of Excellence | Self-Owned Factory | End-to-End Technical

Support

Core Advantage 1: Advanced Engineering for Precision PCB Manufacturing

• High-Density Stack-Up: 2-48 layer boards with blind/buried vias,

3/3mil trace/spacing, ±7% impedance control, ideal for 5G,

industrial control, medical devices, and automotive electronics.

• Smart Manufacturing: Self-owned facility equipped with LDI laser

exposure, vacuum lamination, and flying probe testers, adhering to

IPC-6012 Class 3 standards.

Core Advantage 2: Integrated PCBA Services | One-Stop Turnkey

Solutions

✓ Full Assembly Support: PCB fabrication + component sourcing + SMT

assembly + functional testing.

✓ DFM/DFA Optimization: Expert engineering team reduces design

risks and BOM costs.

✓ Rigorous Quality Control: X-ray inspection, AOI testing, and 100%

functional validation for zero-defect delivery.

Core Advantage 3: Self-Owned Factory with Full Supply Chain Control

✓ Vertical Integration: Raw material procurement, production, and

testing fully managed in-house.

✓ Triple Quality Assurance : AOI + impedance testing + thermal

cycling, defect rate <0.2% (industry average: <1%).

✓ Global Certifications: ISO9001, IATF16949 and RoHS compliance.

Ring PCB not only offers professional PCB manufacturing, but also offer

PCBA assembly service, including component sourcing and SMT service with Samsung

functional machine.

One of our core strengths lies in our 8-stage lead-free reflow

soldering and lead-free wave soldering capabilities at our Shenzhen

factory. These advanced soldering processes ensure high-quality

assembly while adhering to global environmental standards, such as

ISO9001, IATF16949 ,RoHS compliance.

Please note:

All products in our store are processing customized services, please be sure to contact our professional customer service before

placing an order to confirm the product details.

All photos on this site are real. Due to changes in lighting,

shooting Angle, and display resolution, the image you see may have

some degree of chromatic aberration. Thank you for your

understanding.

Ring PCB Technology Co.,Limited is a professional PCB manufacturer with 17 years of history in

China.

Our products are updated and upgraded every year and we specialize

in all kinds of PCB making and PCBA customization services, If you

are interested in our products, please tell us your requirements,

we will help you to provide professional solutions, please contact

us on line or E-mail to us info@ringpcb.com, and we will provide you with one-on-one service from our

professional sales team.

Thank you for your time.